+86 15315361286

+86 15315361286

2021.07.05

EDI (Electrodeionization) is a kind of pure water manufacturing technology that combines ion exchange technology, ion exchange membrane technology, and ion electromigration technology. It skillfully combined electrodialysis and ion exchange technology, using both ends of the electrode high voltage to move charged ions in water, and with ion exchange resin and selective resin membrane to speed up the removal of ions, to achieve the purpose of water purification.

Therefore, the EDI system here is a pure water manufacturing system.

In the process of EDI desalination, ions are removed through the ion exchange membrane under the action of the electric field. At the same time, water molecules under the action of an electric field produce hydrogen ions and hydroxide ions, these ions on the ion exchange resin for continuous regeneration, so that the ion exchange resin maintains the best state.

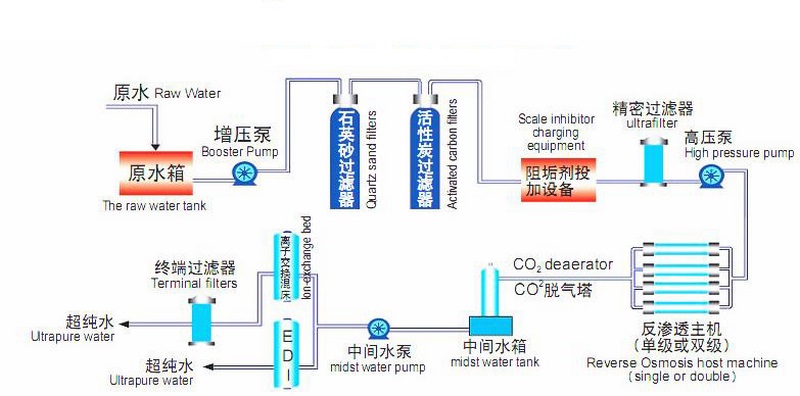

EDI Ultra-Pure Water Equipment Ultra-Pure Water Manufacturing History Process, Stage 1: Pretreatment Filter — >; Yang – bed & gt; Yin – bed & gt; Mixed bed; Stage 2: pretreatment filter — >; Reverse osmosis – & gt; Mixed bed; Current stage: pretreatment filter — >; Reverse osmosis – & gt; Mixed-bed ion exchange (D) has been the standard process for the preparation of ultrapure water for several decades. Because it needs periodic regeneration and consumes a lot of chemicals (acid and alkali) and industrial pure water in the regeneration process, and causes some environmental problems, it is necessary to develop the acid-alkali free ultra-pure water system. Because the traditional ion exchange has been increasingly unable to meet the needs of modern industry and environmental protection, so the combination of membrane, resin, and the electrochemical principle of EDI technology has become a revolution in water treatment technology. The regeneration of its ion exchange resin uses electric energy, and no longer needs acid and base, so it is more satisfied with the environmental protection requirements of today’s world.

1, without acid and alkali regeneration: in the mixed bed resin needs to use chemicals acid and alkali regeneration, and EDI eliminates the treatment of these harmful substances and heavy work, to protect the environment.

2, continuous, simple operation: in the mixed bed because of each regeneration and water quality changes, so that the operation process becomes complex, and EDI water production process is stable and continuous, water quality is constant, there are no complex operation procedures, the operation is greatly simplified.

3 reduce the requirements of installation: compared with the mixed bed with the same amount of water treatment, the EDI system has a smaller volume, adopts the building block structure, and can be flexibly constructed according to the height and scenting of the site. Modular design makes EDI easy to maintain during production.

Ultra-pure water is often used in the microelectronics industry, semiconductor industry, power generation industry, pharmaceutical industry, and laboratory. EDI pure water can also be used for pharmaceutical distilled water, food and beverage production water, chemical plant process water, and other ultra-pure water applications.